Customized double crimp screens

– that fits your application needs.

We design our models around your end product requirements:

configure your double crimp screens parameters.

The requirements for double crimp screens are as individual as their intended use. Aspects like mesh size, wire thickness, and type of material all depend on what need it must fulfill. No matter what your project requires, we’re always happy to offer our professional advice and provide quality double crimp screens tailored to your demands.

Versatile design and quality to depend on

Our double crimp screens are available in the following versions:

untreated

pre-galvanized

stainless steel

(1.4301, 1.4404, 1.4571, 1.4841)

aluminium

(ALMGSI 0,5)

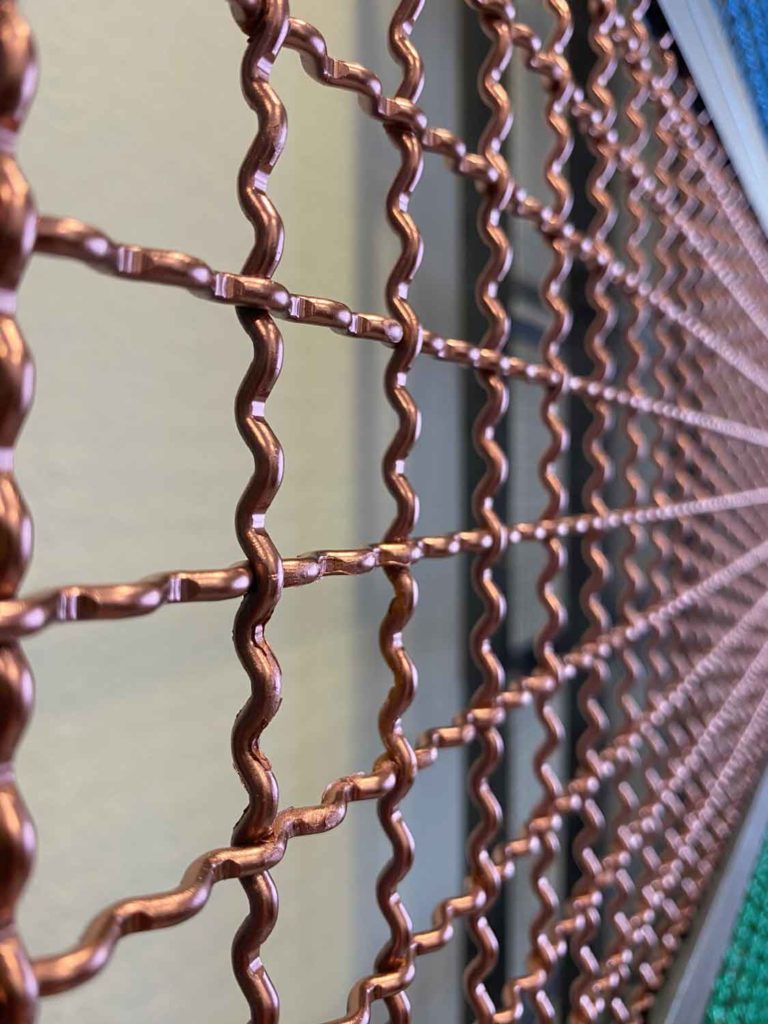

copper

brass

plastic-coated

Wire thicknesses

1,2 - 5,8mm

square or rectangular meshes

5 - 100mm

dimensional tolerances in length and width:

-0 mm / +1 mesh width (standard)

mesh length:

up to 6,000 mm in rolls up to 50 m

mesh width:

up to 2.200 mm

fixed dimensions with tolerances

of + / - 2 mm in length and width on request

You can also choose between wire thicknesses (1,2 – 5,8 mm ) and mesh sizes. Please see our downloadable data sheets for more product information.

Because our double crimp screens are woven from pre-crimped wires, aspects like wire thickness and mesh size can determine the number of crimps within a mesh. Generally, the higher the number of crimps per mesh size, the greater the mesh strength. We are always happy to provide an optimal number to meet your wire mesh needs.

Our custom-made double crimp screens can be found in various industrial sectors. Most of our partners and customers come from the construction & automotive industry, as well as the mechanical engineering sector. Additionally, our high-quality custom-made double crimp screens are used for gates and fences, pigeon control, plant cultivation, container construction, stable animal enclosures, noise protection, and trade fair construction.

Benefit from our comprehensive experience and enjoy long-term success.

As a manufacturer of double crimp screens for over 75 years, we at Draht Binder have accompanied countless projects, advised numerous trade partners, and found various solutions for individual wire mesh end products. Our approach is always solution-driven, and we take pride in our good customer relations and high-quality standards. In short, Draht Binder is your one-stop location for wire mesh you can count on.

- 0211-280 736 - 13

- 0211 / 28 07 36 - 17

- info@draht-binder.de

Individual shapes for special requirements

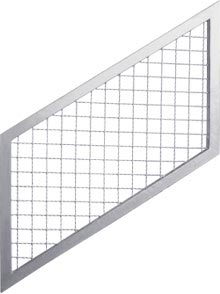

Format A

This wavy mesh is woven horizontally and vertically. It is then cut to the desired size and inserted into a diagonal frame. We only offer this format for small grids.

Format B

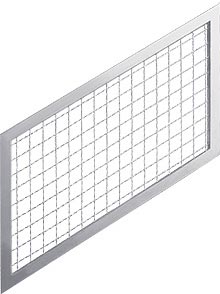

Format C

With this model, the horizontal-vertical woven wavy mesh is cut out diagonally and inserted into a rectangular frame. Due to its attractive appearance, it is very popular and often used and diagonal forces are better absorbed. The process produces more material waste, therefore, we do not offer it in large formats.

Find what you are looking for.

Here, you can find the exact data sheets for all our wire mesh products, including bearing dimensions, weight tables, cribbing, wire thicknesses, material, and more. Just download, configure your product, and order it directly online.

Durable products, fast delivery, reliable logistics.

Would you like personal advice in finding your optimal double crimp screen product? Check out our online inquiry form and let us know your plans and requirements. One of our double crimp screen specialists will personally contact you. That means you are just a few clicks away from your custom-made double crimp screen solution.